Speciality Gas

Special gases are very rare or high purity gases that are generally used in the semiconductor and display industries.

MS Materials can deliver CH3CL, HCL, DMA, TCS, STC and DCS.

Colorless, liquefied gas with the smell of hydrogen chloride. Not explosive, but explosive reactions occur with acetonitrile and diphenylsulfoxide. Reacts violently with alcohol, amine, metal oxide and peroxide, causes corrosive reaction to metal.

- Usage

- chemical vapor, epitaxial silicon deposition (CVD process / EPI)

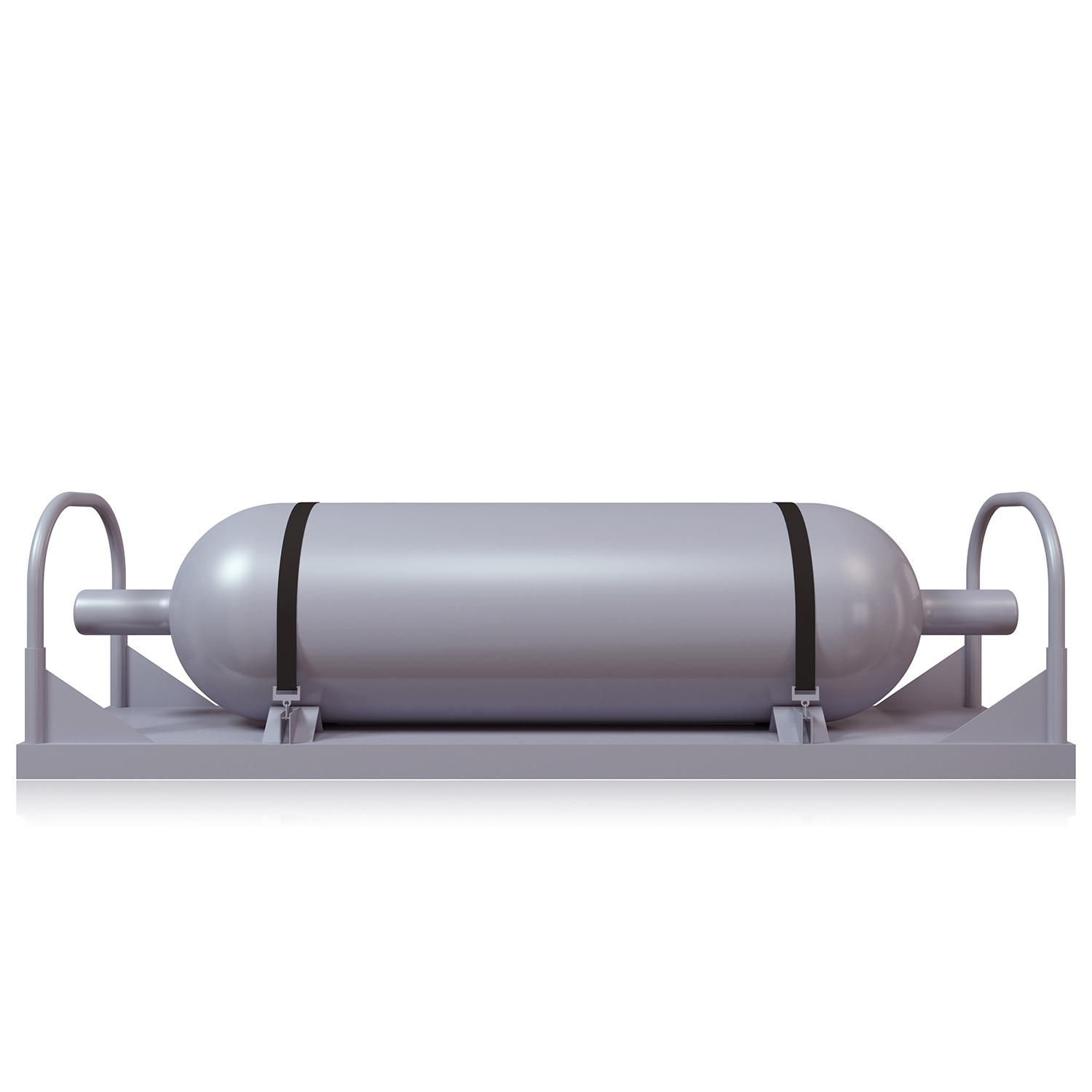

- CYLINDERS

- 60L(60KG) / 210L(250KG)

Colorless, transparent liquefied gas with a strong odor. Reacts with corrosive water or moist air and produces hydrogen chloride and polymeric siloxane, which may ignite spontaneously. Air and mixture may cause explosion when heated in confined spaces.

- Usage

- Nitride film (SiN) deposition in semiconductor manufacturing process / Precursor synthesis raw material

- CYLINDERS

- 10L(9KG) / 40L(35KG) / 44L(41KG) / 440L(450KG) / 995L(900KG)

Colorless, transparent water-soluble liquid with a fishy smell. When reacting with peroxide substances, they can violently decompose and form explosive substances. Do not mix with acids, metals, halogens, combustible substances, oxidizing agents, etc.

- Usage

- Raw materials for rubber chemicals (vulcanization accelerators, anti-aging agents) / paper chemicals and water treatment agents / synthetic raw materials for precursors

- CYLINDERS

- 47L(23KG)

Colorless, transparent liquid vapor liquefied gas with a suffocating odor. Exothermic reaction with water to produce highly corrosive hydrofluoric acid and silicic acid.

- Usage

- Manufacture of tetraalkoxysilane and silica fiber optical waveguide / raw material of silica and hydrogen chloride / synthetic rubber additive

- CYLINDERS

- 47L(30KG) / 60L(60KG)

Colorless or pale yellow liquefied gas with a strong odor. Reacts violently with water to release heat and toxic/corrosive/combustible gases. Strong corrosiveness.

- Usage

- Etching, LCD chemicals, polysilicon manufacturing / Metal surface treatment and water treatment / pesticides, dyes, iron chloride, etc.

- CYLINDERS

- 49L(25KG) / 900L(500KG)

Colorless, transparent liquefied gas with an etheric odor. Do not mix with metals and halogens. Pyrolysis produces phosgene, acid halogen compounds, and carbon oxides.

- Usage

- Organic synthesis (butyl rubber, silicone resin, methylcellulose production) / extractant, low temperature solvent, refrigerant (refrigerant) / medicine, pesticide, foaming agent, non-combustible film

- CYLINDERS

- 1175L(940KG)

Heat Stability

Heat Stability Economic feasibility

Economic feasibility Eco-friendly

Eco-friendly High remove rate

High remove rate Low scratch, defect, dishing

Low scratch, defect, dishing

Quality Mgmt System

Quality Mgmt System

OHSAS 180001 (Safety & Health Management System)

OHSAS 180001 (Safety & Health Management System)

Environment Mgmt System

Environment Mgmt System

Certificate of company affiliated research

Certificate of company affiliated research